Rubber Lagging Sheet

Head drums and drums usually need to be rubber-coated to increase the adhesion and coefficient of friction on the conveyor belt. A smooth rubber coating is generally used for (metal) drums to extend the life of the drum and reduce slurry.

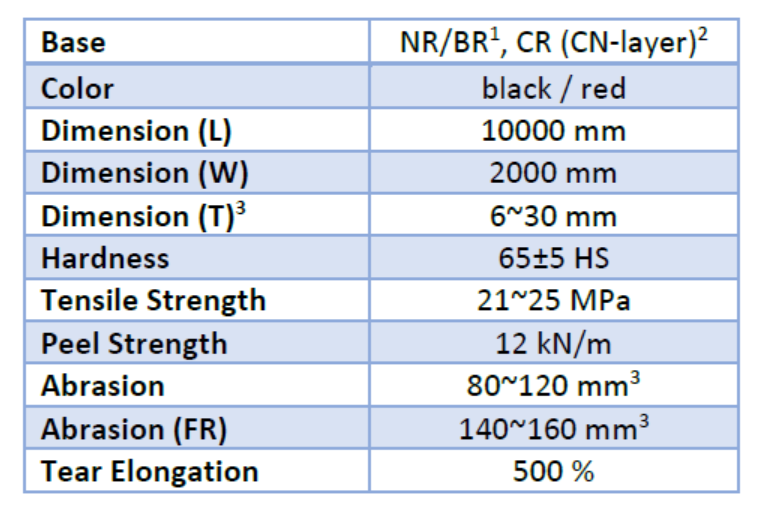

Technical Data

- All Rubber is flame retardance as requirements

- All Rubber can be customized with or without CN-Layer

- Standard: 6/8/10/12/15/20/25mm/30mm......

Features

- Easy, fast and customized montage

- Smooth rotation without clogging of the drums

- Reduction of the slippage between belts and drums

- Decreasing the noise levels and vibrations

- Long service life

Applications

- Pulley lagging

- Vibrating feeder liner

- Slip liner

- Shock absorbers

- Metal-rubber adhesive surface

Available & Storage

- -10~40 °C

- 9~12 months (with CN-layer)

- ≤ 3 years (without CN-layer)

- Storage in a cool, ventilated and dry environment